Oil sludge is a major byproduct of the oil production process. It is a mixture of oil, solid sediment and water that can be highly polluting for the environment but it also has high recycling value. In other words, the oil sludge can be recycled to produce useful products that provide a lot of value by sludge oil recycling plant.

The technology used for converting oil sludge into useful products is known as pyrolysis technology. In this process, the material is heated to a very high temperature in the absence of oxygen which results in breakdown of larger molecules into smaller molecules.

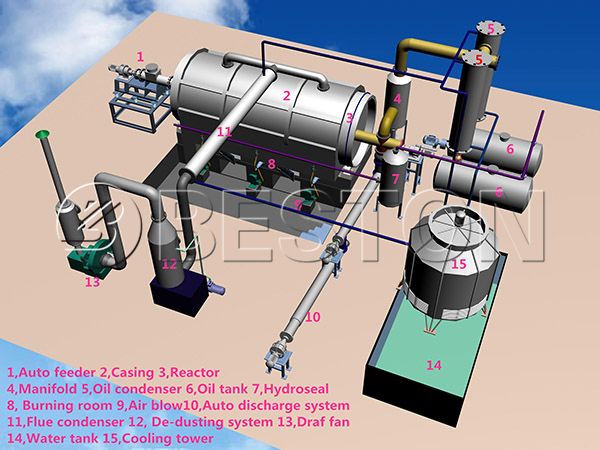

Oil Sludge Recycling Pyrolysis Plant

As mentioned above, oil sludge is harmful for the environment but it can be used in a profitable manner to convert an environmentally harmful product into economically useful products. To convert the oil sludge into useful products, you will need a sludge oil recycling plant.

The oil sludge will be heated to a very high temperature in the pyrolysis reactor, in the absence of oxygen which will result in breakdown of the bigger molecules into other useful products such as fuel oil and other such things.

As far as buying a plant for recycling of oil sludge is concerned, there are hundreds of manufacturers spread all over the world selling a wide variety of these plants. However, there are certain factors you need to consider in order to choose the right plant.

One of the most important things you need to look at is the efficiency of the plant. Some plants available in the market use technology that converts a significant amount of oil sludge into useful end products. Therefore, the first thing you need to look at is the efficiency of the plant.

Another important thing you need to look at is the safety of oily sludge treatment plant. There are some manufacturers who cut corners and deliver a lower quality plant that may not be as safe to operate as one believes. Therefore, you need to check the reputation of the manufacturer in order to make sure that they deliver a high quality plant that is completely safe to operate.

The plant should capture the exhaust gases for recycling to be used again in the heating process. It not only saves a lot of fuel but also helps in reducing pollution.

It should also come with a built-in system to clean the exhaust gases in order to comply with the local environmental regulations. Some manufacturers supply high quality plants where filters are used to clean the gases before the gases are allowed to release.

The plant should also make it easy for the operators to feed the raw materials without moving the base. Ideally, there should be a conveyor belt attached to the plant in order to move the raw material into the reactor in an easy manner.

And of course there is that issue with plastics being bad for the environment and mother earth. A wise businessman would heed the warnings of these environmentalists. After all, they are egg customers too and their numbers seem to increase by the minute.

And of course there is that issue with plastics being bad for the environment and mother earth. A wise businessman would heed the warnings of these environmentalists. After all, they are egg customers too and their numbers seem to increase by the minute.