Do you have a lot of waste plastic that has to be tossed out? Do you have to toss it out or can you do something with it? Plastic is great as a resource because it has use after it has been thrown out. You don’t just discard plastic and leave it like that.

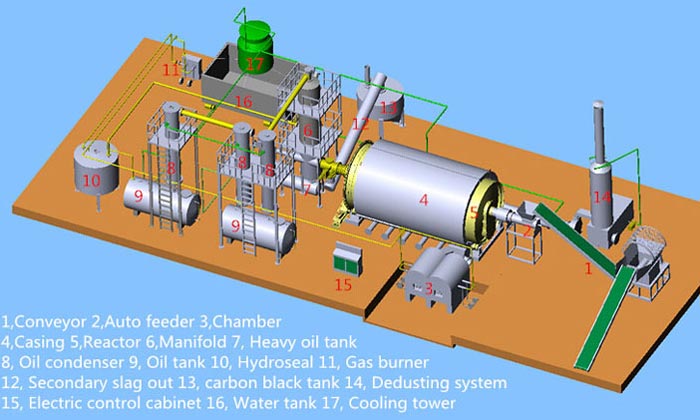

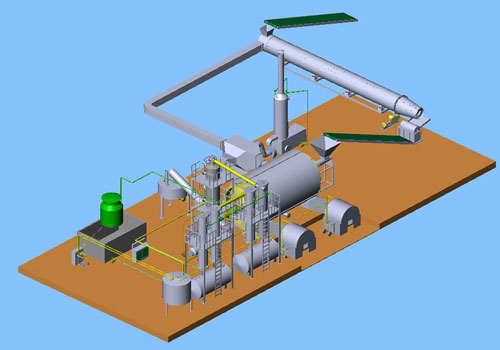

In the past, this was possible where people were dumping plastic and technology had not hit a height where there was more use to it. Now, there are machines which can turn that same plastic into oil for you in large batches, it is called as the waste plastic to oil machine for sale in Kingtiger.

Sounds nice, but how do you get a good one machines for recycling plastic that will last? Let’s see.

Make Sure Conversion Is Pure

What about the oil that will be coming out of the machine? Will it be pure or is it going to lack that purity to it that you want? There are some lower priced machines that won’t give you pure oil and those are the worst. All of that work only to get oil that doesn’t hold value is meaningless.

You have to learn and look at the output you are getting not in terms of the quantity, but in terms of the actual oil itself.

Find A Great Seller Immediately

You want a person who is able to give you a good deal and is reliable. They should be a person that has done this before and has buyers who are willing to vouch for him/her. You want this because sometimes the conversions are just not pure enough and the machine might not even work.

You can’t put money into something that is average in quality.

Even worse, you could be duped into making a purchase that is not good at all. This is when you know you have been scammed.

Look into the best pyrolysis machine manufacturer for your own sake.

Don’t Be Fooled By Low Price

There are certain sellers who want to just get rid of a machine and will lower the price. It will look amazing on paper and you will want to put the cash in and get it. Sure, you might get a good deal now, but when you bring it over and start using it, the problems will become telling.

You will start to see how the pyrolysis machine price was just a way of clearing the machine. It will never run well.

Price being low is nice, but can’t be the only thing with a machine such as this.

Plastic is such a great resource and you can turn it into oil within months. You should be able to get it processed through the machine and out into your liquid inventory within no time. In fact, there are many large producers who are not churning out so much and making millions because of the work they do.

You have to think about how you will get the plastic to turn into oil as well. Get a good machine first, and make sure the machine uses the most advanced pyrolysis process.