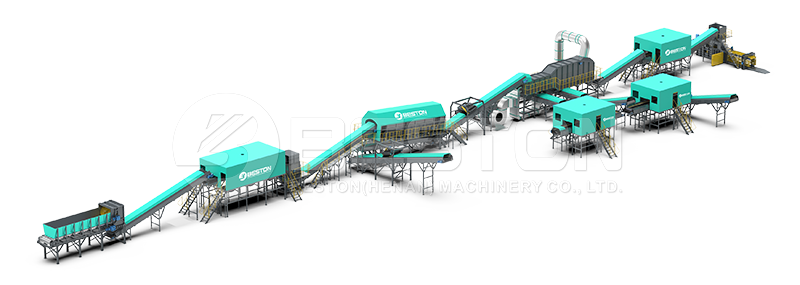

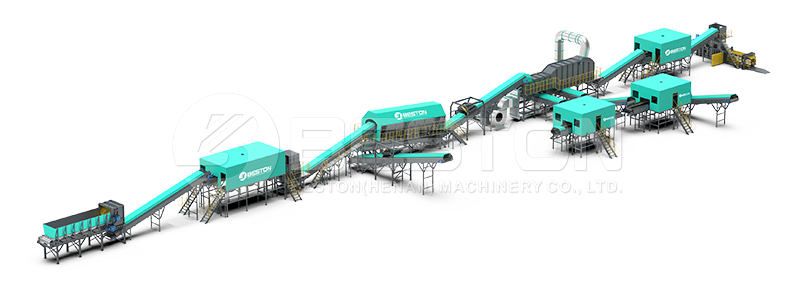

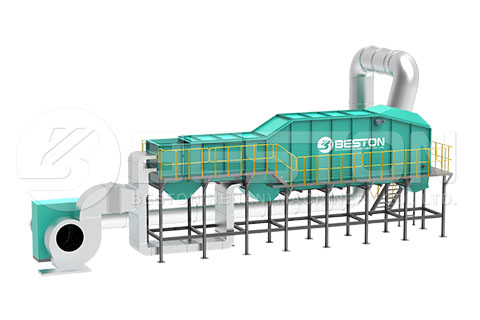

We all produce huge amounts of waste that can be collected and turned into something useful. Local authorities and governments strive to make it easy for their communities to contribute to the recycling of all this stuff they don’t need any longer. Sorting this waste to prepare it for the recycling process is one of the biggest challenges authorities have to face. A municipal solid waste sorting machine is a must for all communities that want to contribute to turning waste into different other products.

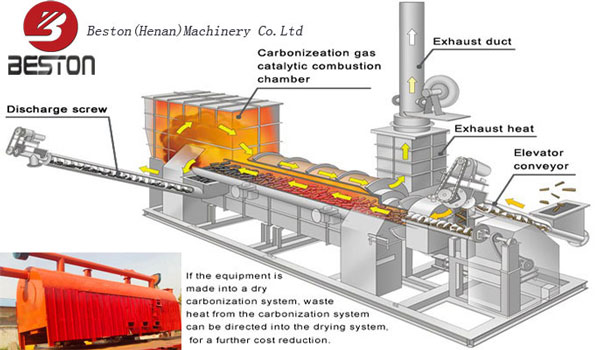

The first step in choosing the right equipment is to understand how such machines work. At the same time, you should become aware of the four main categories of waste, in order to determine the best methods to remove and sort them. Basically, you’ll need to deal with four types of solid waste: metal, plastic, organic matter, and constructions materials. Each of them has its own characteristics. For instance, we all know that magnets attract metals, so we can easily understand how a magnetic remover can extract all metal items and separate them from the waste. While as for plastic, rubber, etc. we can employ further processing equipment, for example, you can find pyrolysis plant for sale.

The magnetic remover is only one of the modules you’ll need your ideal municipal solid waste sorting machine should have. You’ll also need something to separate plastic. As this material is lighter than other types of waste, a centrifugal module will easily separate it. Furthermore, by using a device with wholes of two sizes, you’ll be able to perform two sorting activities at the same time. Better work efficiency leads to a higher productivity rate, so it’s always something to look for when shopping around for such machines.

Centrifugal modules are also able to separate organic matter and compact it into bricks that will follow along the recycling process. All these modules and devices work together and this is how these solid waste sorting machines are capable of doing a very good job. They are not only faster than humans, but they are also more accurate. All these mechanisms are designed to minimize error, hence being superior to human labor.

In order to make the right choice, you have to know all these very well. You also need to communicate with the companies that are going to handle the next stages of the recycling cycle. If you don’t have the equipment to turn waste into something else, you’ll have to deliver it to someone who does. These companies need to know how they are going to receive their raw matters to use in their production processes. All these details will influence the technical specifications of your waste sorting machine.

Last but not least, you should seek for at least three or four quotes from different suppliers. For best results, consider searching directly for waste recycling plant manufacturer rather than buying from third party agents. Once you get all your cost estimates, compare them closely to see which one best suits your needs. By paying close attention to all stages of the purchasing process, you’ll invest in a reliable machine to serve your community for many years to come.