Plastic pollution has become one of the most pressing environmental challenges of our time. With millions of tons of plastic waste generated annually worldwide, finding effective solutions to manage and mitigate this problem is imperative. Among the array of approaches, plastic pyrolysis has emerged as a promising technology with numerous advantages in addressing the plastic waste crisis. In this blog post, we will explore the benefits of plastic pyrolysis and its potential to revolutionize waste management practices.

- Resource Recovery: Plastic pyrolysis machine involves the thermal decomposition of plastic waste in the absence of oxygen, resulting in the conversion of plastics into valuable products such as liquid fuels, gases, and solid residues. This process enables the recovery of energy and materials from non-recyclable plastics that would otherwise end up in landfills or incinerators. By extracting value from plastic waste, pyrolysis offers a sustainable alternative to traditional waste disposal methods, reducing the strain on finite resources and mitigating environmental impact.

- Waste Diversion: One of the primary advantages of plastic pyrolysis is its ability to divert plastic waste from landfills and oceans. Instead of accumulating in the environment for hundreds of years, plastics can be transformed into useful products through pyrolysis, thereby closing the loop on the plastic waste stream. By diverting plastic waste from disposal sites, pyrolysis helps alleviate the burden on waste management infrastructure and reduces the risk of environmental pollution, preserving ecosystems and wildlife habitats. More information on TDU.

- Energy Recovery: Plastic pyrolysis generates a range of energy-rich products, including pyrolysis oil, syngas (synthetic gas), and char. These products can be utilized as alternative fuels for various applications, such as heating, electricity generation, and industrial processes. Pyrolysis oil, in particular, can serve as a substitute for conventional fossil fuels like diesel and gasoline, offering a renewable and cleaner energy source. By harnessing the energy content of plastic waste, pyrolysis contributes to energy security and reduces greenhouse gas emissions associated with fossil fuel combustion.

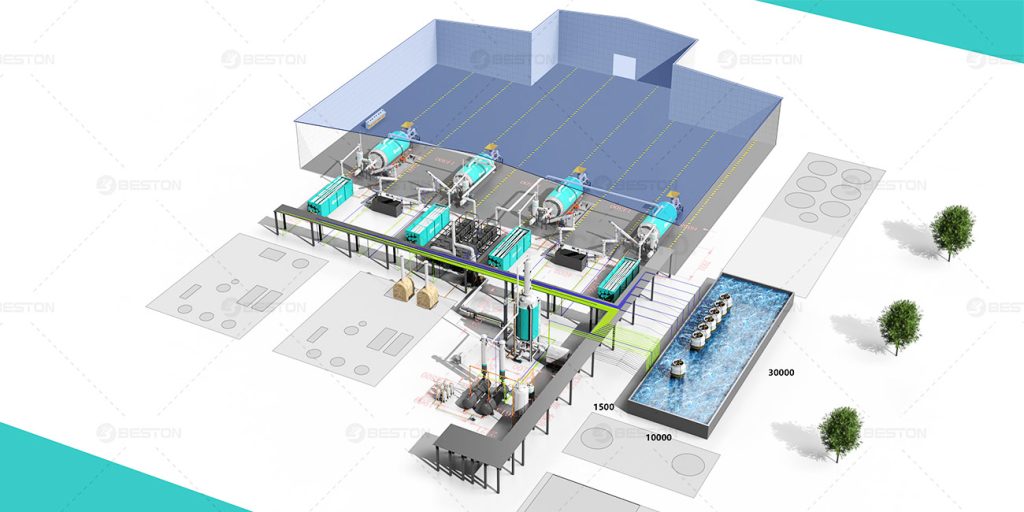

- Versatility and Scalability: Plastic pyrolysis is a versatile technology that can accommodate different types of plastic feedstocks, including mixed or contaminated plastics that are challenging to recycle through conventional methods. Additionally, pyrolysis plants can be scaled to meet varying demand levels, from small-scale facilities for localized waste management to large-scale operations for municipal or industrial applications. This scalability makes pyrolysis adaptable to diverse waste management needs and enables its implementation in a wide range of settings. See continuous waste tyre pyrolysis plant here.

- Environmental Benefits: Compared to traditional waste disposal methods like landfilling or incineration, plastic pyrolysis offers several environmental benefits. It reduces greenhouse gas emissions by preventing the release of methane from decomposing plastics in landfills and minimizing the combustion of plastics in incinerators. Additionally, pyrolysis can help mitigate air and water pollution associated with plastic waste, as the process is conducted in a controlled environment with minimal emissions and effluents.

- Circular Economy Potential: Plastic pyrolysis aligns with the principles of the circular economy by facilitating the conversion of waste into valuable resources. The products obtained from pyrolysis can be reintegrated into the production cycle, serving as feedstocks for new materials or energy sources. This closed-loop approach maximizes resource efficiency, reduces dependence on virgin materials, and promotes a more sustainable model of consumption and production.

In conclusion, plastic pyrolysis offers a multifaceted solution to the challenges posed by plastic waste, providing resource recovery, waste diversion, energy recovery, versatility, scalability, environmental benefits, and circular economy potential. While the technology is not without its challenges, such as cost-effectiveness and environmental concerns, ongoing research and development efforts are continuously improving the efficiency and sustainability of pyrolysis processes. As we strive to combat plastic pollution and transition towards a more sustainable future, plastic pyrolysis stands out as a promising tool in our arsenal of waste management strategies. Also, you can find waste tire pyrolysis plant here.