The latest reclamation technologies and processes have started to change the method by which oil refineries used to process materials, which now does not involve incineration or disposal. TDUs, which are short for Thermal Desorption Units are used in several different industries for heating contaminated materials to a high temperature for long enough so that the materials dry and the contaminants are vaporized from them.

What Is Thermal Desorption?

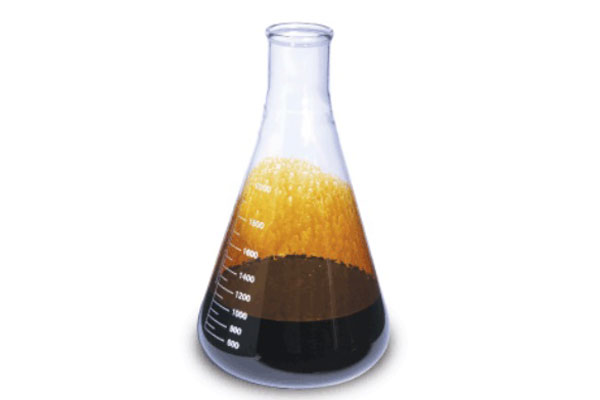

Thermal desorption is described as a type of reclamation process that separates hydrocarbons from different material types. These processes use very high heat for reclaiming oil or other types of materials with the use of non-incineration and non-contact technology. Thermal desorption unit is used commonly for processing organic materials like oil-bearing materials from different refineries.

How Does Thermal Desorption Work?

When heat is applied to contaminated materials, these materials (with low boiling points) will turn into vapor. The vapor is collected and undergoes treatment inside an off-gas treatment unit. The waste removal of the pyrolysis machines allows for these contaminated materials to be recycled or repurposed without any problems associated with contamination.

What Is A Thermal Desorption Unit?

With a Thermal Desorption Unit, the contaminated materials are indirectly exposed to the heat inside a drum that turns slowly which is directly exposed to heat around the exterior shells. The vaporized contaminants then separate from the solid waste, which results in end products that are easy and cost-effective to dispose of.

The common design for these units is the rotary desorber that includes a cylindrical, rotating metal drum. In direct-fired rotary disorders, the contaminated materials enter a rotating cylinder that is heated directly by a flame or the hot gas that comes off the flames. In indirect-fired rotary disorders, the materials are not in contact with the combustion gases or the flame. In these setups, the exterior of the rotating metal cylinder will be heated. The heated metal will then indirectly heat the materials tumbling inside. As the materials start to heat up, any contaminants that are present will vaporize and form part of a stream of gas air and the contaminated vapors that flow through the desorber into a post-treatment system.

If you’re ready to invest in this machine, please visit this website: https://bestonasia.com/how-much-does-a-pyrolysis-plant-cost/.

In some cases, non-reactive gas, like nitrogen will be added into the stream of gas to stop the contaminants that are now vaporized from igniting or catching on fire inside the Thermal Desorption Unit and to assist in removing and vaporizing the contaminants.

Why Consider Thermal Desorption?

The process of thermal desorption is an effective method to separate organics from popular products such as paint wastes, waste produced through wood treatment, coal tar waste, and refining wastes. This process can effectively separate pesticides, solvents, PCBs, fuel oils, and dioxins from materials that are contaminated such as soil. The equipment in Beston Group that is required to achieve these tasks can treat as much as 10 tons of contaminated material such as soil per hour. Another reason why many facilities prefer thermal desorption units is that use a lot less fuel when compared to many other types of treatment methods.