Advantages Of Continuous Tire Pyrolysis Plants

There are many great benefits of continuous tire pyrolysis plants. To begin with, such plants can operate around the clock, as there is no need to cool the reactor down between batches. Instead, raw materials can be fed into the reactor automatically on a continuous basis. The collection of end products is also automatic thanks to the discharging systems within continuous pyrolysis plants.

Another benefit of continuous pyrolysis plants is that they generally have very high safety ratings. All of the components and systems that make up such plants are computer controlled and they have many fail-safe mechanisms built in to protect the safety of all employees within a plant.

Perhaps the main reason that operators choose fully continuous waste tire pyrolysis plants over manual batch processing plants is that they have much lower labor costs associated with them. Automatic plants also have much higher efficiency ratings and can process several tons of waste materials each day. Continuous tire pyrolysis plant price is often linked to the quantity of raw materials the plant is capable of processing each hour. Top of the range models can processes 24+ tons of waste rubber each day.

Profitable Commodities

The final products produced by a continuous tire pyrolysis plant are fuel oil, carbon black and combustible gas. All of those products are profitable commodities in their raw state and can be sold to many different industries. The fuel oil produced is often sent for further refinement in a distillation machine, so it can be turned into diesel to generate enhanced profits for plant operators. Carbon black can also be manufactured into charcoal blocks to increase its value in the marketplace.

The reality is that it is possible to make a lot of money running a continuous tire pyrolysis plant, especially if you are able to acquire the raw materials needed to run your plant cheaply. If you live an area where the disposal of waste plastic and scrap tires is becoming a big problem, you should find it easy to source cheap raw materials to keep your continuous tire recycling pyrolysis plant running. Keep in mind that plants can process a wide range of raw materials beside scrap tires, including rubber, oil sludge, and waste plastic.

Different Models And Manufacturers

On the internet, you can find out the current average continuous tyre pyrolysis plant price. There are many different manufacturers in the industry selling a wide range of different models of pyrolysis reactors for the processing of waste tires. It’s essential to compare the pros and cons of each model carefully. You can often download detailed PDF specification sheets from manufacturers’ websites, as well as request free quotes. Note that you need to compare as many factors as possible, as the cheapest machinery is not always the best option.

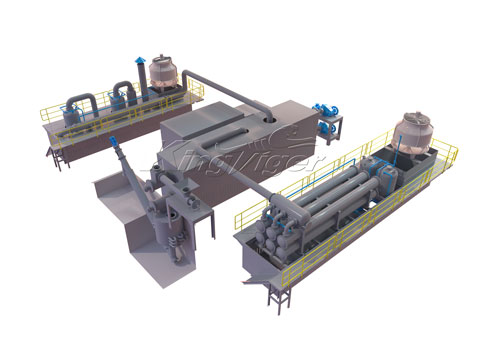

Some of the factors you need to compare are energy running costs, maximum daily processing capacity, reactor fuel options, reactor size, working method, cooling method, operating pressure, required floor area, total power, reactor pattern, and service life. With regular maintenance, the average plants have a service life span of seven years.