Did you know that if you have bamboo charcoal making machine, you can manufacture charcoal from bamboo? Not only is bamboo a number one food source for pandas, but it has many other types of uses and applications. Bamboo is a plant that grows very quickly in warm regions of the world such as South America, Asia, and Africa. Bamboo charcoal is similar to wood charcoal and coconut charcoal in that it has a very vital role in different human activities. In addition, it is also an expensive product because it is a great raw material for activated carbon.

So, if you live in an area that has an abundance of naturally growing bamboo, you should consider investing in a bamboo charcoal making machine. Because bamboo charcoal is such a profitable end product, it will not take you very long to recoup your investment.

How To Process Bamboo To Convert It Into Charcoal

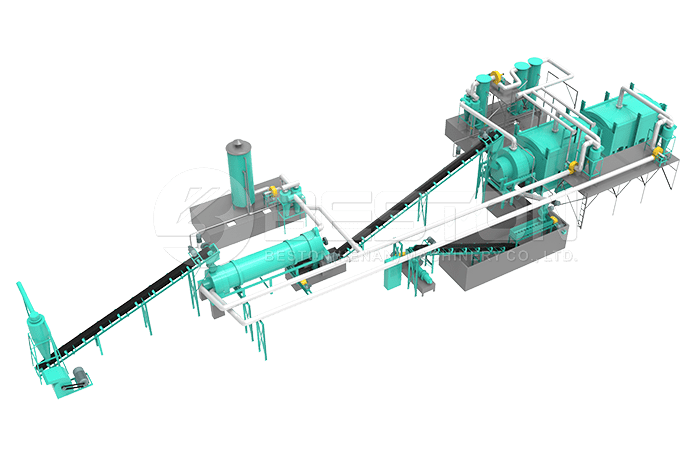

The first thing that you should do is collect and shred the bamboo into small pieces, and then put the pieces on the conveyor belt. Then, transport the bamboo into the weight feeder. This constant weight feeder will divide the bamboo into the top layer for drying and flash steaming and into the bottom layer for carbonization. Biomass pyrolysis of the bamboo occurs. After the carbon collection and discharge and removal of sulfur and smoke, you will have natural bamboo charcoal.

The process works as follows. There is one fire that is used in order to raise the temperature of the heat carbonization. Any residual heat that is left over after the process is complete is used as a heating supply for the drying host. There is a casing that surrounds the operator and keeps it from being affected by the carbonization host’s high heat. Here is a video for your reference. Also, you can find more information on blogs.

Safety

What Are The Features Of Bamboo Charcoal Making Machine?

This type of charcoal making machine offers many features that help to make it not only an affordable piece of machinery but a high-efficiency piece of equipment.

Energy Efficiency

Charcoal making machine from Beston Machinery is very energy efficient even though the actual process is high efficiency. There are two features within a bamboo charcoal making machine that makes it very efficient. The first feature is the “One Fire, Two Steps” design, which can make full use of the heat. The second one is the biomass carbonization plant from Beston can recycle the combustible gas produced during biomass pyrolysis process.

Bamboo charcoal making machines also contain a PLC system that helps operators control and monitor temperature, pressure and the alarm system in real time. This display system also helps to ensure that operators remain safe while using the machine. These machines also have a built-in professionally sealed system that keeps all of the working system of the machine safe, and this system ensures the carbonization host is protected and sealed.

Eco-Friendly

Many charcoal making machines on the market do not have specialized cooling and dedusting systems. It is important to look for a manufacturer that offers these features in their machines so help keep pollution out of the air and environment. Here is a website for your reference to find eco-friendly biochar production equipment: https://mswrecyclingplant.com/biochar-production-equipment/.

Efficiency

As previously mentioned, these types of machines are very efficient. In fact, the furnace temperature for the carbonization host is typically between 400 and 600 degrees C. As a result, the higher the temperature gets, the higher the working efficiency of the machine will be.

Obviously, it is a great investment to have a bamboo charcoal making machine. Why don’t you contact Beston Machinery for more details?