Producing charcoal with a machine is becoming a common business model. Whether you are utilizing rice hulls, sawdust, coconut shells, or some type of other organic material, it’s very easy to do. The technology that is incorporated into these machines is exceptional, and they have become extremely elaborate over the years. If you want to find one to expand into this profitable business model, you can find the right charcoal making machine for sale by using the following tips.

How Does A Charcoal Machine Convert Materials Into Charcoal?

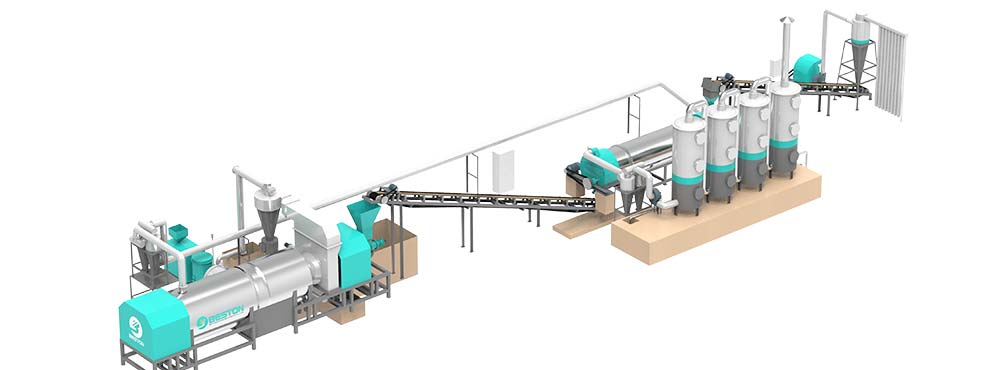

The materials that it uses must have some type of a carbon containing component. Essentially, it needs to be an organic substance that is burnable. If it does, this can be converted into charcoal through a process called pyrolysis. During the burning process, the combustion of the material is possible because of fuel, heat and oxygen. If you remove the oxygen from the equation, the heat and fuel together will lead to a chemical change, creating the charcoal that is produced by these machines. As long as you have an ample supply of these materials, especially on a continual basis, this could become a very profitable business venture for your company. Click here to know more: https://bestonpyrolysisplant.com/.

The prevalence of these machines is becoming quite normal on a worldwide scale. This is especially true in areas of the world where charcoal is in demand. For example, in the US, charcoal is typically used by civilians for leisurely purposes. It is seldom used for the purpose of heat or cooking food on a daily basis. In other areas of the world, that is exactly what charcoal is used for and why it is in demand. If you have a coconut farm, or if you harvest rice annually, you can benefit from providing charcoal to those that need it the most. Therefore, to find the best machines available, simply start searching in countries where these machines are likely to be used. This will enable you to find them, evaluate them, and choose one that has affordable pricing.

How To Choose The Best One For Your Particular Business

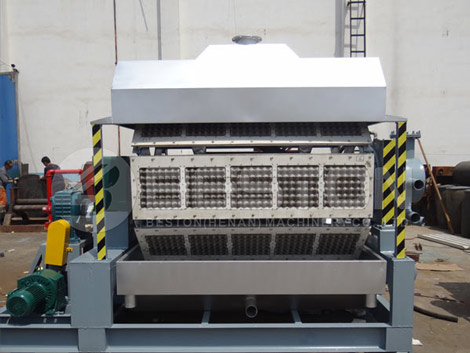

If you have a lumber mill, rice farm, or if you are responsible for drawing coconuts, this is a coconut shell charcoal making machine for sale you certainly need to have. Keep in mind that these are actually quite elaborate, taking up a sizable amount of space, and you must go through specific training on how to set them up and use them. Once this is all done, it will become straightforward to produce charcoal by breaking down the initial materials into smaller components and heating them in the pyrolysis chamber. Once you know what to do, and you have buyers that want your product, this is where it becomes very profitable.

Purchasing a charcoal making machine is becoming commonplace. There are so many individuals and businesses that are doing this today. You will want to choose one that can keep up with the amount of production that you are capable of producing. Some people invest in ones that are larger, just in case they decide to expand their business or get access to more of this organic material that can be used. You will eventually locate the best one for your company, one that will be affordable and will also produce massive quantities of charcoal that you can sell. More information on the blog: https://bestoncompany.blogspot.com/.