In an era of growing environmental concerns and a heightened focus on sustainability, innovative solutions for waste management and renewable energy sources are essential. One such solution is the Sawdust Charcoal Making Machine, a remarkable invention that transforms sawdust waste into valuable charcoal. This revolutionary technology not only reduces waste but also provides an eco-friendly alternative to traditional charcoal production methods.

I. The Mechanism of Sawdust Charcoal Making

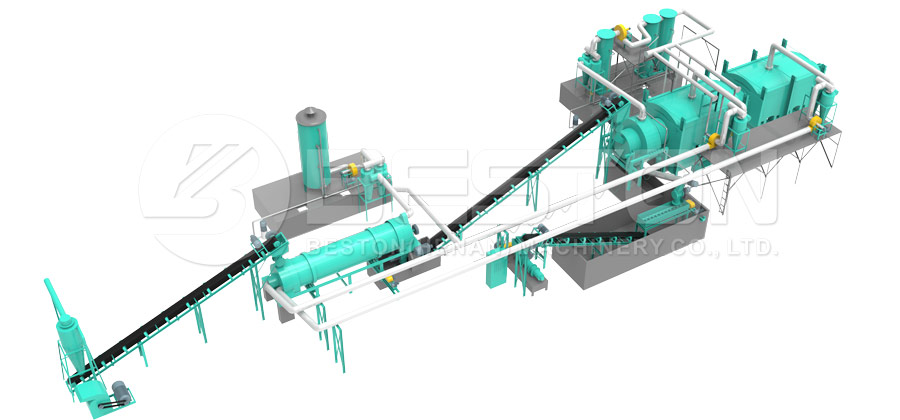

The sawdust charcoal making machine operates on the principle of pyrolysis, a process that involves the thermal decomposition of organic materials in the absence of oxygen. This technology effectively converts sawdust, a waste product from wood processing, into high-quality charcoal.

Feeding and Heating: The process begins by feeding the sawdust into a specialized chamber within the machine. It is then heated to high temperatures in the absence of oxygen, typically between 300°C to 600°C.

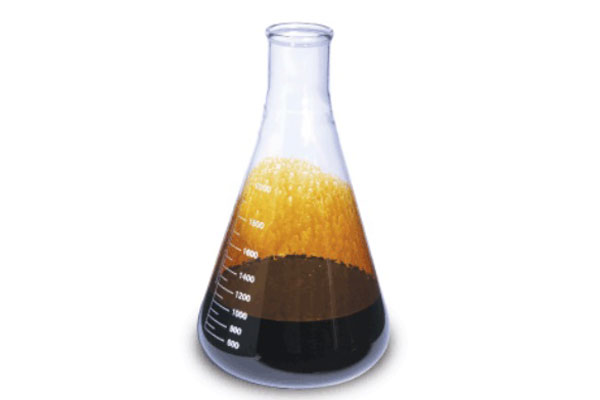

Pyrolysis Reaction: As the sawdust heats up, it undergoes a chemical transformation known as pyrolysis. During this phase, the organic compounds in the sawdust break down into volatile gases, bio-oil, and charcoal.

Gas and Smoke Removal: The volatile gases and smoke produced during pyrolysis are captured and condensed. This process not only prevents harmful emissions but also yields valuable byproducts such as wood vinegar and tar.

Charcoal Collection: The final product, charcoal, is collected and can be further processed and shaped into various forms, such as briquettes or activated charcoal.

II. Environmental Benefits

The sawdust charcoal making machine offers a multitude of environmental benefits, making it a game-changer in the quest for sustainability.

Waste Reduction: One of the most significant advantages is its ability to effectively utilize sawdust waste, reducing the burden on landfills and minimizing environmental pollution.

Carbon Neutral: The carbon footprint of sawdust charcoal production is substantially lower compared to traditional methods, as it recycles carbon dioxide already present in the atmosphere. This makes the process close to carbon-neutral.

No Deforestation: Unlike conventional charcoal production that often leads to deforestation, sawdust charcoal making relies on wood industry byproducts, thereby reducing the demand for fresh timber and protecting forests.

Clean Energy: The resulting charcoal can be used as a clean-burning fuel source, reducing the reliance on fossil fuels and decreasing greenhouse gas emissions.

III. Economic Advantages

The carbonizing machine that turns sawdust into charcoal also offers several economic advantages, which make it an attractive investment for both individuals and industries.

Cost-Effective: By using sawdust waste as a raw material, businesses can reduce waste disposal costs and generate an additional revenue stream from the sale of charcoal and its byproducts.

Job Creation: The operation and maintenance of these machines create job opportunities in local communities, contributing to economic growth.

Energy Independence: The availability of a renewable and clean energy source reduces dependence on expensive fossil fuels and fluctuating energy prices.

IV. Potential Applications

The versatility of charcoal makes it a valuable commodity for a variety of industries, and the Beston Group sawdust charcoal making machine opens up numerous applications:

Cooking and Heating: Charcoal produced by this machine can be used for cooking, heating, and grilling, providing a cleaner and sustainable alternative to traditional charcoal.

Agriculture: The bio-oil and wood vinegar byproducts can be used as organic fertilizers, enhancing soil fertility and crop yield.

Water Purification: Activated charcoal, a derivative of the process, is widely used in water purification systems to remove impurities and toxins.

Metallurgy: Charcoal can serve as a reducing agent in metallurgical processes, replacing coal and coke with a more eco-friendly option.