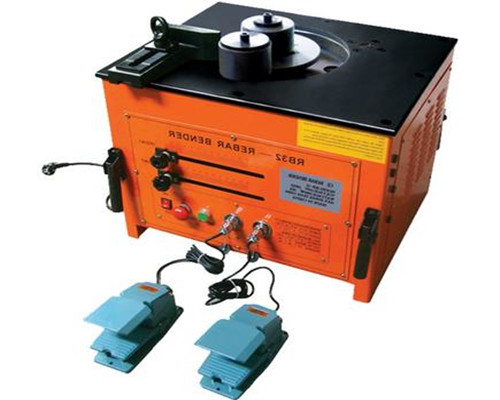

Reinforcement bending machines, also known as rebar benders, are machines utilized to bend bars made of chemical toxins like steel among others. This equipment is quite normal around construction sites and enable users to bend very heavy steel bars ?like those employed in reinforcement ?at accurate angles.

When operating any machine, users should take some precautionary measures to ensure that they do not hurt themselves and also to ensure that the safety of other folks around them. The identical is applicable to people using a reinforcement bar bending machine.

In the following paragraphs, we shall be discussing some basic, yet essential precautionary measures to think about when you use a rebar bending machine.

Look at the Instruction Manual

Reinforcement bending machines are heavy, powerful machines which can be to never be operated by an inexperienced individual. Before operating a rebar bender, it is crucial that there is a good understanding of how the machine functions and ways to operate it. As a result, if you are operating this machine the very first time, it is far better you get some training from a person with rebar bending machine operation experience. You would get more information about how to operate reinforcement bending machine after check video on Youtube.

Wear Protective Gear

Using a reinforcement bending machine may be risky. Since you will be utilizing heavy metal pieces and steel bars, it is essential that you handle them carefully. As the prospect of object dislocations or accidents taking place is very high, it is preferable that you simply wear protective gear like goggles, thick gloves, and protective footwear to minimizes odds of getting hurt.

Consider Hand Placement

When bending metals by using a rebar bender, it is vital that you be cautious with the place you place both hands. Be mindful and cautious as soon as the machine starts bending the bar being worked on to the machine roller as any carelessness can lead to permanent injuries or serious accidents.

Heat Up the equipment For a few Minutes in Cold Temperatures

For safe operation and for the greatest results during cold temperatures, it is crucial that you, to begin with, heat the equipment for several minutes before operating it. Accomplishing this helps set the appliance in motion and is also beneficial because it lowers stress in the bender itself.

Always Hold Metal Bars Parallel for the Bender

The appropriate angling and placement of metal bars play a major role in terms of getting the right metal bends and in guaranteeing safety. You will be, therefore, advised to pick the right bending angle and to make sure that you place the machine rebar parallel to its bender table before starting any bending. Wrong placement could result in the rebar to bend bars at incorrect angles. There is also a likelihood of the bar hitting you, ultimately causing injury.

Operate the Machine Foot Pedal properly

Reinforcement bending machines have got a foot pedal which is used to regulate bending direction. To protect yourself from injuries and bending mistakes, it can be imperative that you person operates both foot pedal and bar bender. If more one than person operates the different parts of the appliance, the probability of any sort of accident happening will probably be extremely high.

In terms of working with a reinforcing steel crooking machine, it is important that you operate the equipment only if you are fit and in the correct senses. Never operate this machine should you be not fully alert or conscious, or are under the influence of medication, drugs, or alcohol as rebar bender accidents could be lethal not only to you but additionally to fellow workers near or close to you.