Wood processing industries generate significant amounts of waste, posing environmental challenges. However, wood pyrolysis plants offer a promising solution by transforming this waste into valuable resources. Pyrolysis, a thermal decomposition process in the absence of oxygen, efficiently converts wood residues into biochar, bio-oil, and syngas. This article explores the principles, benefits, and applications of pyrolysis technology in wood waste recycling.

Understanding Pyrolysis

Pyrolysis is a complex thermochemical process wherein organic materials are decomposed at elevated temperatures (typically 300-800°C) in an oxygen-starved environment. This process induces chemical reactions, leading to the breakdown of complex organic molecules into simpler compounds. In the context of wood waste recycling, wood pyrolysis plant offers a sustainable approach to convert biomass into valuable products.

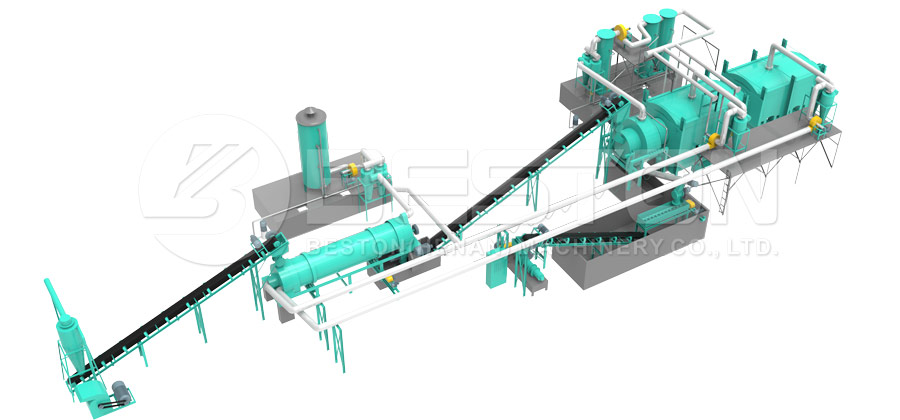

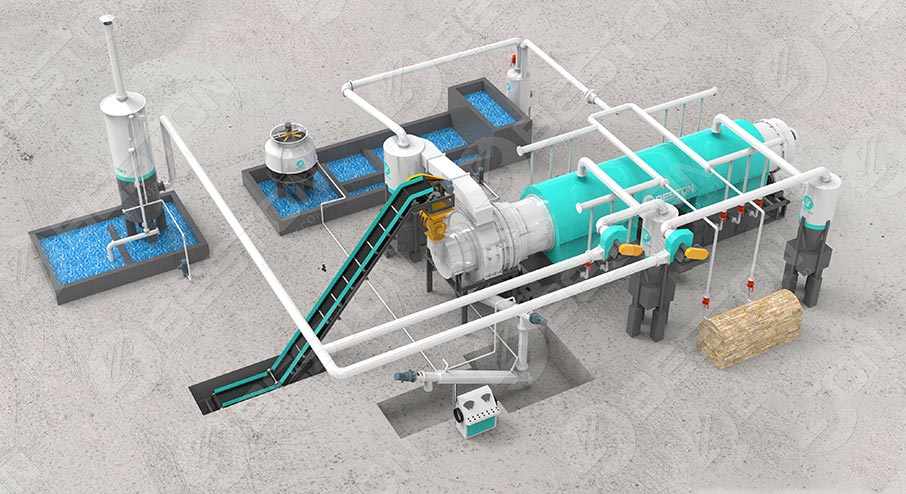

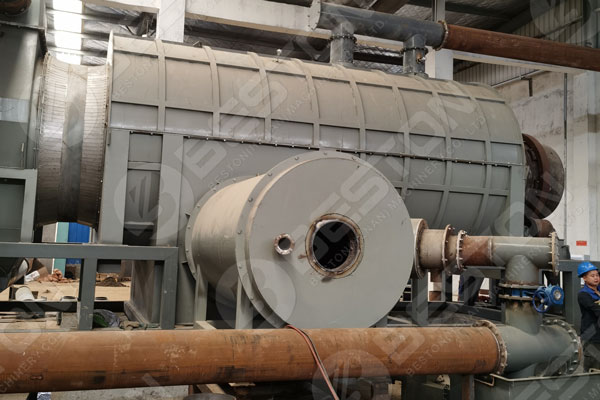

The Role of Wood Pyrolysis Plants

Wood pyrolysis plants serve as the focal point for implementing pyrolysis technology. These facilities are equipped with specialized reactors designed to optimize the pyrolysis process. Wood waste, including sawdust, wood chips, and forestry residues, is fed into these reactors, where controlled heating induces thermal decomposition. The resulting products, namely biochar, bio-oil, and syngas, hold immense potential for various industrial applications.

Product Yield and Composition

The pyrolysis process in wood to charcoal machine yields three primary products:

- Biochar: A carbon-rich solid residue obtained from the pyrolysis of wood. Biochar serves as a valuable soil amendment, enhancing soil fertility and carbon sequestration.

- Bio-oil: Also known as pyrolysis oil or wood tar, bio-oil is a dark, viscous liquid containing a complex mixture of organic compounds. It finds applications as a renewable fuel source or as a precursor for biochemical production.

- Syngas: A mixture of carbon monoxide, hydrogen, and other gases produced during pyrolysis. Syngas is a versatile energy carrier used in power generation and industrial processes.

The composition of these products varies depending on factors such as feedstock type, pyrolysis conditions, and reactor design.

Environmental Benefits

Wood pyrolysis technology offers several environmental advantages:

- Waste Reduction: By converting wood waste into valuable products, pyrolysis mitigates the environmental burden associated with landfill disposal or incineration.

- Carbon Sequestration: Biochar produced during pyrolysis acts as a stable carbon sink when applied to soil, effectively sequestering carbon and mitigating greenhouse gas emissions.

- Renewable Energy: Bio-oil and syngas derived from wood pyrolysis serve as renewable alternatives to fossil fuels, reducing reliance on non-renewable resources and lowering carbon emissions.

Applications of Pyrolysis Products

The products obtained from wood pyrolysis find diverse applications across various industries, Beston Company has developed corresponding application plans based on these industries:

- Agriculture: Biochar serves as a soil conditioner, improving soil structure, nutrient retention, and water retention capacity. Its use promotes sustainable agriculture and enhances crop productivity.

- Energy Generation: Bio-oil and syngas can be combusted directly or further processed to generate heat or electricity. These renewable fuels offer a viable alternative to conventional fossil fuels, supporting the transition towards a low-carbon economy.

- Chemical Industry: Bio-oil serves as a feedstock for the production of platform chemicals, biofuels, and specialty chemicals. Its diverse composition makes it suitable for a range of downstream applications, including chemical synthesis and bio-based product manufacturing.

- Waste Management: Wood pyrolysis technology provides an environmentally sound solution for managing wood processing waste. By converting waste into valuable resources, it helps reduce reliance on landfilling and promotes a circular economy model.

Challenges and Future Outlook

Despite its potential, wood biochar pyrolysis equipment faces certain challenges, including:

- Economic Viability: The initial capital investment required for establishing wood pyrolysis plants may be substantial. Achieving cost competitiveness with conventional waste management practices remains a key challenge.

- Feedstock Availability: Ensuring a consistent supply of suitable feedstock for pyrolysis operations is essential. Wood waste collection and logistics pose logistical challenges that need to be addressed for the widespread adoption of pyrolysis technology.

- Technology Optimization: Continuous research and development efforts are needed to optimize pyrolysis processes, improve product yields, and enhance overall efficiency.

Despite these challenges, ongoing advancements in pyrolysis technology hold promise for the widespread adoption of wood waste recycling practices. With the integration of innovative process designs, improved reactor technologies, and enhanced product utilization strategies, wood pyrolysis has the potential to emerge as a cornerstone of sustainable waste management and renewable energy production.

In conclusion, wood pyrolysis technology offers a sustainable and environmentally friendly approach to wood processing waste recycling. By harnessing the principles of thermochemical conversion, pyrolysis transforms wood residues into valuable products, thereby mitigating environmental impact and supporting the transition towards a circular economy. As research and development efforts continue to drive innovation in this field, the future looks promising for the widespread adoption of pyrolysis technology in wood waste management.