One of the most exciting technologies making a difference is pyrolysis, a process that transforms waste materials into valuable resources like oil. Pyrolysis plant manufacturers such as Beston Group are at the forefront of this industry, producing innovative machines that help convert waste plastic and tyres into fuel oil. This article delves into how plastic to oil machines and tyre to oil plants are changing waste management for the better.

The Growing Importance of Pyrolysis Technology

Global waste production, especially from plastics and used tyres, is a mounting issue. Plastic and rubber materials, while convenient, are notoriously difficult to decompose and typically end up in landfills, where they leach chemicals or in oceans, harming wildlife. Pyrolysis, a technology that heats these materials in the absence of oxygen, offers an innovative way to break down waste and extract valuable products. This method can be used to produce oil, carbon black, and syngas, creating a sustainable cycle and reducing the environmental impact of waste.

Plastic to Oil Machine: A Sustainable Solution

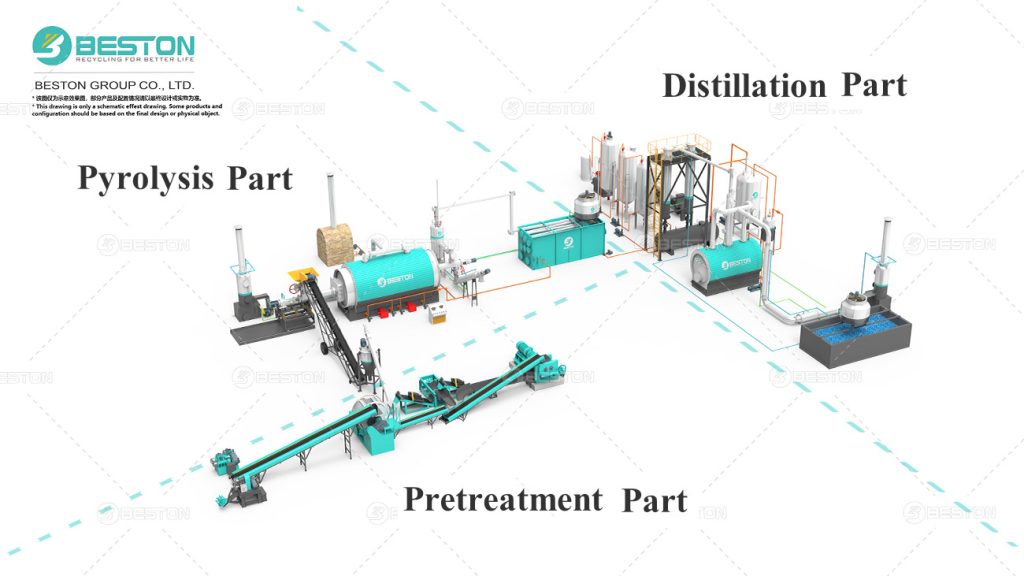

The plastic to oil machine is one of the most effective tools for addressing plastic waste. Through the pyrolysis process, waste plastic is heated in an oxygen-free chamber, which breaks down the polymers into oil, carbon black, and gas. This oil can then be used as fuel, helping offset the need for petroleum-based fuels.

Beston Group, a leader in pyrolysis technology, has engineered plastic to oil machine with high-efficiency, low-emission designs. Their machines are capable of processing various types of plastic, from household waste to industrial plastic, providing communities and businesses with a reliable way to turn their plastic waste into a usable energy source. These machines have become a popular choice for companies and municipalities looking to reduce landfill waste while generating additional revenue through oil production.

Tyre to Oil Plant: Breathing New Life into Waste Tyres

Similarly, the tyre to oil plant is an innovative solution to the vast problem of used tyre disposal. Old tyres pose environmental and health risks, from leaching chemicals into soil and groundwater to creating breeding grounds for mosquitoes. The tyre pyrolysis process involves heating tyres in a high-temperature, oxygen-free environment, where they decompose and produce oil, carbon black, and steel wire.

Beston Group’s tyre to oil plant are designed with the latest technology, making them highly efficient and easy to operate. Not only do these plants recycle waste tyres, but they also generate high-quality oil that can be used in industries such as manufacturing, construction, and even energy production. This oil can be refined further or used directly as an industrial fuel, offering an eco-friendly alternative to fossil fuels.

Why Choose Beston Group as Your Pyrolysis Plant Manufacturer?

Beston Group has become a recognized name among pyrolysis plant manufacturers. With years of expertise in the waste recycling industry, they have developed a full line of pyrolysis machines tailored to meet the needs of businesses and governments alike. Here are a few reasons why Beston Group is a preferred choice:

- Advanced Technology: Beston Group utilizes cutting-edge technology to ensure their pyrolysis plants are efficient, reliable, and environmentally friendly.

- Customizable Solutions: Beston’s range of pyrolysis machines comes in various capacities and designs, enabling clients to select the equipment that best fits their needs, whether it’s for plastic waste, used tyres, or even medical waste.

- Focus on Sustainability: Beston Group is committed to sustainability and circular economy principles. Their machines not only reduce waste but also create usable, eco-friendly products, contributing to a cleaner, greener planet.

- Global Reach and Service: With a strong global presence, Beston Group provides exceptional customer service and support, ensuring clients have the resources they need to operate their pyrolysis plants smoothly and efficiently.

The Future of Pyrolysis: Sustainable Waste Management

The increasing demand for sustainable waste management solutions and renewable energy sources makes pyrolysis technology a promising avenue for innovation. Companies like Beston Group are helping to lead the way by producing advanced, efficient pyrolysis plants that enable communities to manage waste in an eco-friendly, profitable manner.

As waste continues to be a global challenge, pyrolysis plant manufacturers like Beston Group are providing effective solutions through plastic to oil machine and tyre to oil plant. These innovations not only help reduce waste but also offer an opportunity to turn trash into treasure by producing usable oil, carbon black, and other by-products. By investing in these technologies, businesses and governments can move closer to achieving their sustainability goals while supporting a circular economy.

With the help of advanced pyrolysis solutions, we can look forward to a future where waste is minimized, resources are recovered, and our planet becomes a cleaner, greener place.