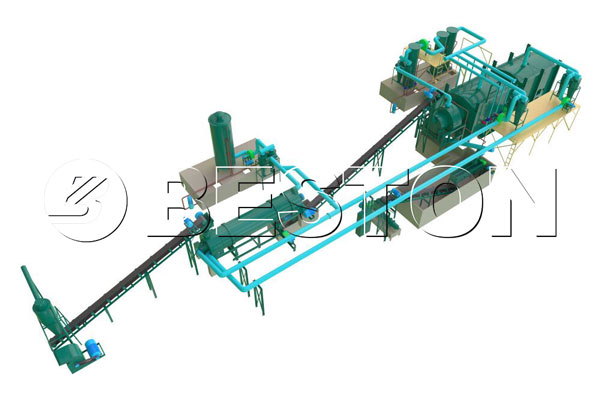

If you are looking for a biochar machine for sale, find it online is a good way. Recycling is the biggest thing of this century. As natural resources become scarce, people seek for alternative ways to manufacture things they need from items they no longer use. Biomass, for instance, is the perfect raw matter to turn into charcoal. Let’s see where you can find biochar reactor and what to look for in such equipment.

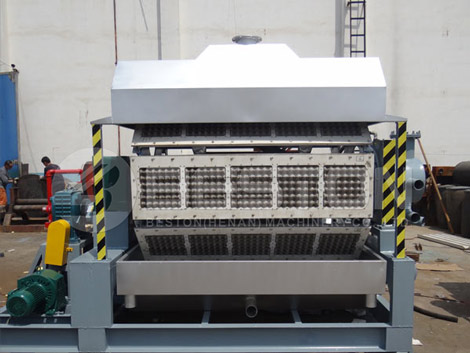

The easiest method to find such machines is to search online for manufacturers. This is a very competitive market, so you can rest assured you’re going to find lots of sellers of different types of biochar machine for sale that can process olive seeds, coconut shell, rice hull and wood, among many other organic matters. Your biggest challenge is going to be to pick the right equipment for you. The best way to do it is to collect information about as many machines and manufacturers as you can, and then compare them side by side, with their advantages and drawbacks.

There are business and trade directories that include a recycling equipment section. Check them out to see what you can find. AliBaba is one of the best places to start your research from. Their biochar machine for sale selection is nothing short of impressive. You’ll find lots of models of rice husk biochar making machines, sawdust carbonization furnaces, wood briquette carbonization equipment, and many other such devices. Watch some of the presentation videos, reach out to some of these manufacturers, and try to gain a better understanding of the really important features to look for in such a device. Here are a few of the main factors to take into consideration when making your purchasing decision. There is a reference for you: https://BestonTurkey.com/.

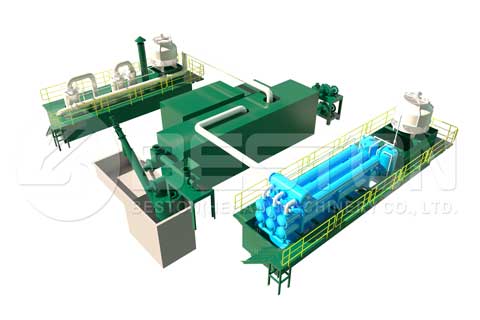

The technology is important, because it has a direct influence on the amount of fuel required. For instance, the combustible gas reburning system uses waste gas to generate heat in a very energy-efficient manner.

The protection of the environment is another thing you should carefully consider. As biochar machine for sale generates smoke, you should seek for effective smoke purification systems, in order to run your business in an environment-friendly manner. There are biochar carbonizer brands that come with smoke flue condenser, water spray, water washing and ceramic ring absorption, to name only a few of the systems that guarantee a pollution-free recycling process.

Safety is also one of the major concerns of many biochar machines manufacturers. It should be one of your main concerns, too. Always seek for reliable and effective safety features, as this is how your manufacturing plant and your workers will be safe. The best biochar making plant should feature an explosion-proof design and a fully sealed production process. The sealing prevents oxygen from entering the reactor, thus eliminating the explosion risk. Click this link for more information.