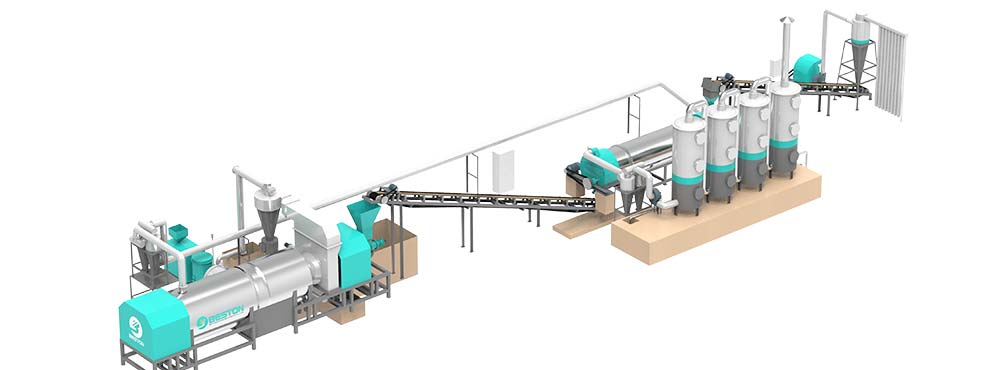

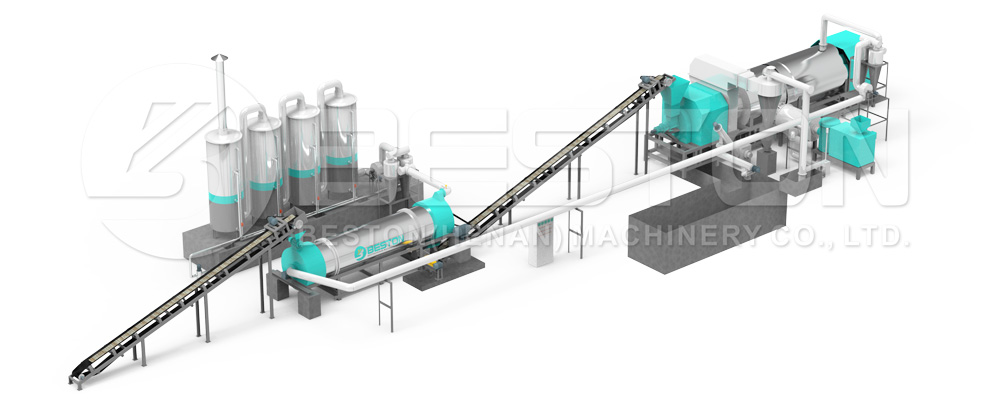

When you need an affordable way to turn biomass into charcoal or oil, a biochar machine is a great choice to help you produce large amounts of charcoal. This machine takes many different kinds of biomass, including sawdust, wood, rice husk, straw and more. The biochar machine is efficient and it is affordable to run. It also doesn’t produce a lot of emissions which makes it a good choice for people who care about the environment.

The charcoal that the machine produces is high-quality and it burns for a long time which means you can get a lot of use out of it. The charcoal also doesn’t produce much smoke which makes it a great choice when you need top quality charcoal for your application.

The charcoal is used for heating and cooking. It is also used in fertilizer and other different products. When you need to produce charcoal it is important that you use a machine that is reliable and that also doesn’t create pollution in the environment.

The raw materials that the machine uses are very easy to find and they are also very affordable. The machine helps

you to turn them into something useful. The manufacturer can help you choose the right machine so you end up with a machine that is just right for your needs and is also good for the environment since it takes waste materials and gets them out of the landfills and it also allows for easy operation. Click here to know more about coconut shell charcoal making machine.

The machine is designed to use low amounts of energy which makes it affordable to run. You won’t have to worry about spending a lot of time fixing the machine or trying to deal with technical issues. The support team will be there around the clock to help you with any issues you are having.

When you are looking for a biochar machine it will be very important that you do your research so you find the machine that is the best fit for your needs. You want to look around for a machine that is going to suit your needs the best and provide you with the best return. If you need help, the manufacturer can help you choose the right wood charcoal making machine for your situation. A good biochar machine is going to be a great investment for your business and it will help you make more money when you need to expand.