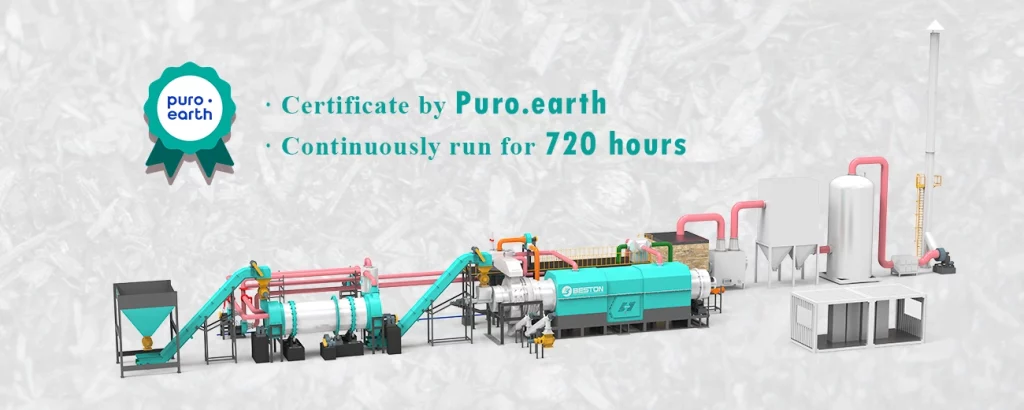

In the dynamic landscape of the global environmental technology industry, a significant partnership has emerged. Beston Group has successfully become the pyrolysis technology provider for Puro.earth, a remarkable achievement marked by the passing of its biochar production equipment, also known as biomass pyrolysis plants or biochar pyrolysis machines, through Puro.earth’s rigorous evaluation.

The Rising Demand for Sustainable Pyrolysis Solutions

In recent years, the world has witnessed an escalating demand for sustainable solutions to combat environmental challenges. Pyrolysis technology, which converts biomass or waste materials into valuable products like biochar, bio – oil, and syngas, has come to the forefront. Puro.earth, with its unwavering commitment to carbon – negative initiatives, has been actively seeking advanced pyrolysis technology to enhance its projects. Beston Group, with its long – standing reputation in environmental technology, was a natural candidate for this collaboration.

The Stringent Evaluation Process

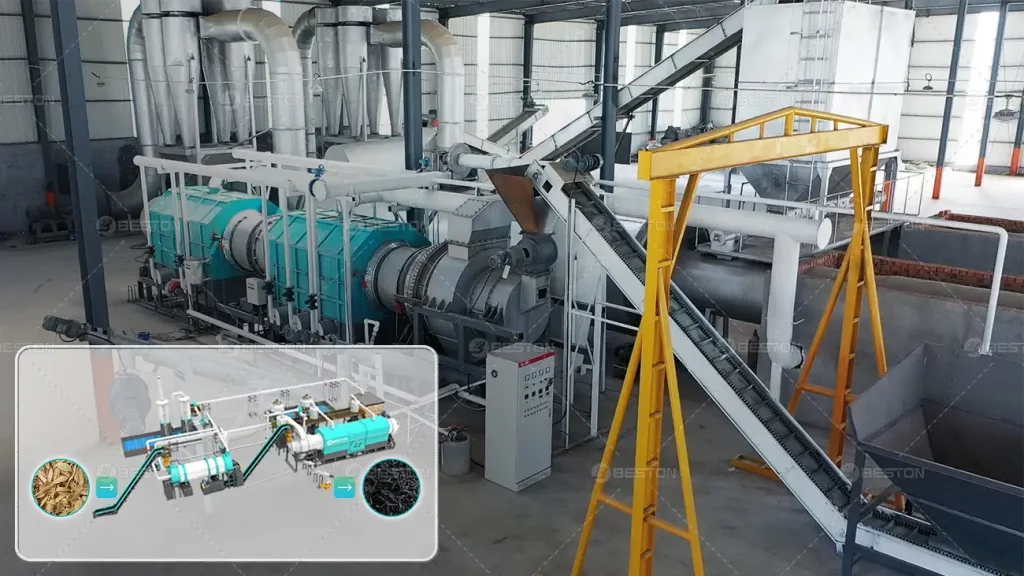

Puro.earth’s evaluation process was nothing short of meticulous. Their team of experts delved deep into the technical aspects of Beston Group’s biochar production equipment. They scrutinized the equipment’s ability to handle various biomass feedstocks, such as wood chips, agricultural residues, and even some types of industrial waste. The energy efficiency of the biomass pyrolysis plants was a key focus. The evaluation aimed to determine how much energy was required to convert the biomass into biochar and other by – products, as well as how efficiently the equipment could operate over an extended period.

The quality of the biochar produced by the biochar pyrolysis machines was also a critical factor. Puro.earth’s standards demand biochar with high carbon content, suitable porosity, and excellent nutrient – retention capabilities, as these properties are essential for its applications in soil amendment, carbon sequestration, and water purification.

Advantages of Beston Group’s Equipment

Beston Group’s pyrolysis machinery to produce biochar stood out during the evaluation due to several key features. Firstly, it incorporates state – of – the – art automation technology. This allows for precise control of the pyrolysis process, ensuring consistent and high – quality biochar production. Operators can monitor and adjust the temperature, pressure, and feed rate of the biomass in real – time through a user – friendly interface, minimizing human error and maximizing production efficiency.

Secondly, the equipment is designed with energy – recovery systems. During the pyrolysis process, a significant amount of heat is generated. Beston’s equipment captures and reuses this heat, reducing the overall energy consumption and making the production process more sustainable. This not only benefits the environment but also lowers the operating costs for Puro.earth.

Another advantage is the modular design of the biomass pyrolysis plant. This design enables easy installation, expansion, and maintenance. Whether Puro.earth needs to scale up its production capacity in the future or perform routine maintenance tasks, the modular structure ensures that the process is hassle – free and cost – effective.

The Significance of the Partnership

The successful evaluation and subsequent partnership between Beston Group and Puro.earth hold great significance. For Puro.earth, it means access to reliable and advanced pyrolysis technology that can help them achieve their carbon – negative goals more effectively. The high – quality biochar produced by Beston’s equipment can be used in a wide range of projects, from large – scale agricultural soil improvement to urban greening initiatives.

For Beston Group, this partnership serves as a testament to its technological prowess and innovation in the field of pyrolysis. It also provides an opportunity to expand its global footprint and contribute to the worldwide efforts in environmental protection. The collaboration is likely to drive further research and development in pyrolysis technology, leading to even more efficient and sustainable biochar pyrolysis machine.

In conclusion, the collaboration between Beston Group and Puro.earth marks a new chapter in the development of pyrolysis technology. As they work together, we can expect to see more innovative solutions emerging in the field of sustainable energy and environmental protection, bringing us closer to a greener and more sustainable future.