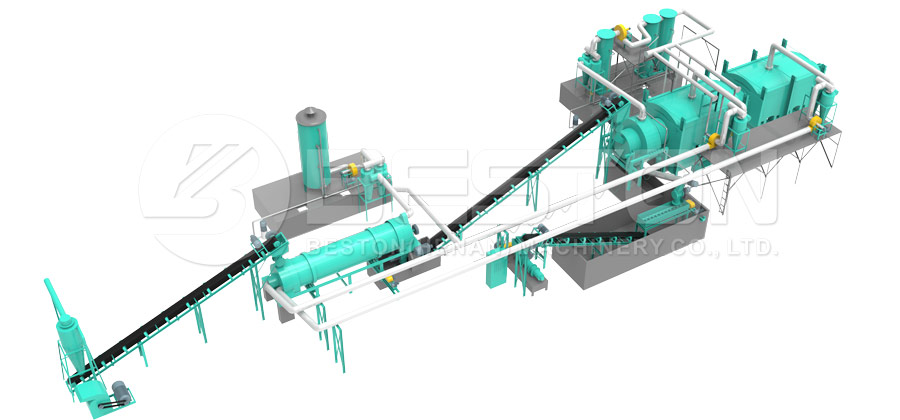

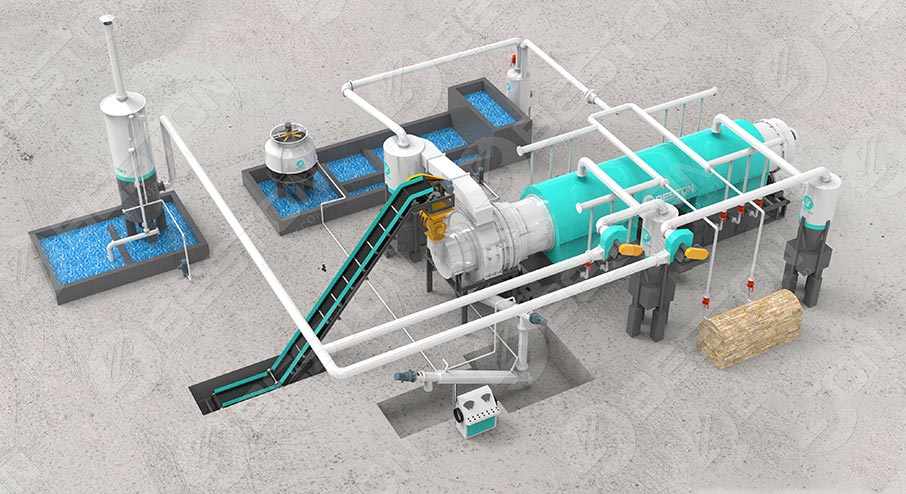

When it comes to waste management, pyrolysis is one of the most important processes. A pyrolysis plant project report can be beneficial in understanding the process and its potential implications. The plant converts waste materials into useful products like fuel oil and carbon black. Waste tires are a good example of a material that could be used in a pyrolysis plant project report. By understanding the benefits and challenges of this technology, municipalities can make more informed decisions about their waste disposal options.

There are many factors to consider when designing or implementing a pyrolysis plant project report, such as space availability, feedstock selection, and output product demand. It is important to have a clear understanding of these factors before making any decisions about building or using a pyrolysis plant.

The Benefits of Creating a Pyrolysis Plant Project Report

A municipality’s purchase of a pyrolysis plant is a major investment. The municipality wants to make sure that it is making an informed decision about the best waste disposal option for its particular circumstances. It will want to know the answer to several questions before making a final decision:

-Does the pyrolysis plant have a good track record?

-What are the operating costs?

-What are the maintenance costs?

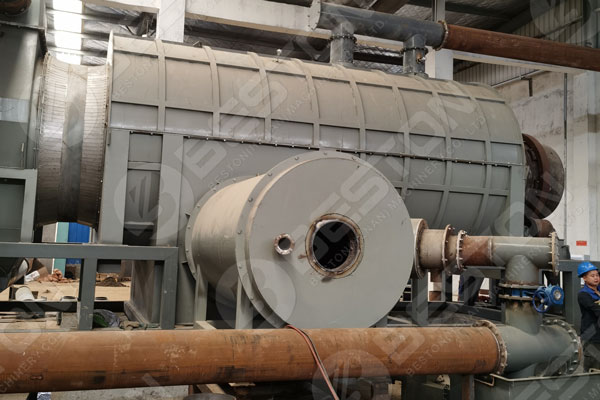

-What is the expected lifespan of the plant?

-How much waste does the plant process?

-What is the end product? Does the end product have any market value?

A pyrolysis plant project report can help answer these questions and provide the municipality with the information it needs to make an informed decision. More information on Beston Group here.

Factors to Consider When Designing Or Implementing a Pyrolysis Plant Project Report

1. Space availability

When designing or selecting a pyrolysis plant, it is important to consider the space availability at the site where the plant will be located. The plant will need to be able to process the waste material in an efficient manner, and it must have enough space to store the end products.

2. Feedstock selection

It is also important to consider the feedstock selection. The type of waste material that will be processed by the pyrolysis machine will determine the size and type of plant that is needed.

3. Output product demand

The output product demand must also be considered. The plant must be able to produce the desired quantity of fuel oil and/or carbon black. By measuring demand for these products, it becomes easier to gauge the ROI that the plant can generate.

4. Other considerations

Other factors, such as waste disposal regulations and environmental impact, must also be taken into account.

The municipality should consider all of these factors when designing or selecting a pyrolysis plant. A pyrolysis plant project report can help to identify the best plant for the municipality’s particular circumstances.

While creating a pyrolysis plant project report can be a time-consuming process, it is important to have a clear understanding of the benefits and challenges of this technology. This information can help municipalities make more informed decisions about their waste disposal options and guide their other actions that relate to helping conserve the environment. Get pyrolysis plant cost here.