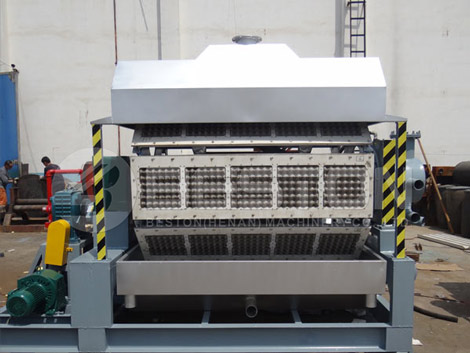

Investors are seeking for garbage recycling plants. Over a half a century ago, there was a movement that was started to launch the environmental movement of today. 20 million Americans from every walk of life activated Earth Day. It is movements like this that have helped to take the waste and recycling industry to the next level. The garbage recycling machines for sale are good project for recycling waste. Use egg tray machine for sale to recycle paper waste.

Even with the awareness of Earth Day, the United States is producing more waste than ever before in history. However, these negative impacts on the environment are in fact decreasing in part because of innovations and investments that are being made in the waste and recycling industry.

From garbage disposal to garbage collection to garbage processing, the biggest waste companies in the United States are reconsidering how waste is handled, and how garbage recycling plants can enhance the protection of the environment.

The following describes in greater detail the aspects of the industry where investment and innovation has made a huge difference.

Garbage Recycling

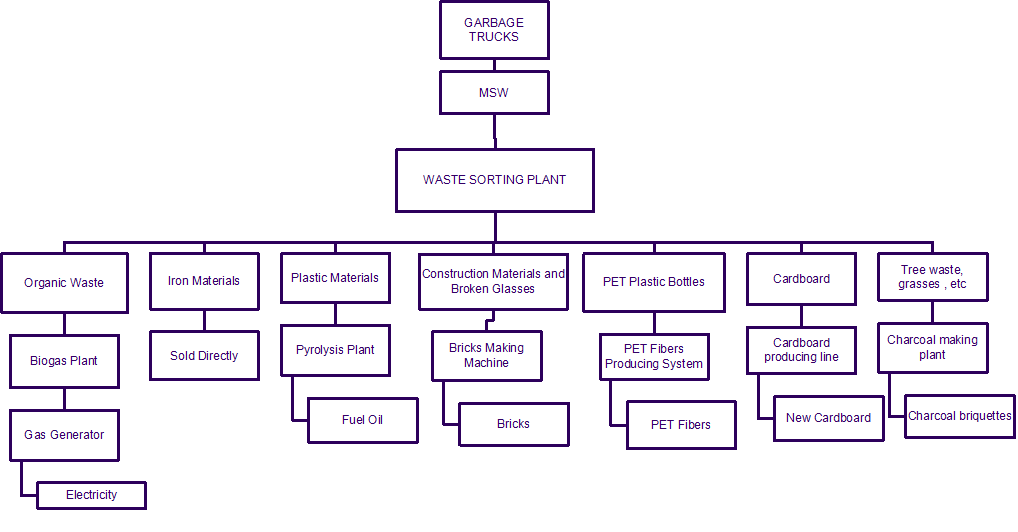

Recycling companies and waste companies are continuously investing in improving techniques and processes related to waste and recycling. As a result, these improvements have led to changes in single-stream recycling. Some solid waste management plant manufacturers provide turnkey project. Apply sawdust pellet machine to recycle biomass waste.

Single-stream recycling is a process where customers simply dump all of their waste into one bin, and the recycling companies use machines to sort through the waste for them. As a result, recycling rates improve and the burden of sorting these materials is taken off of the customer.

With this type of recycling process, it also helps the environment because fewer trucks are needed on the road. This helps to reduce emissions.

Disposal And Collecting Technology

This type of technology has been on full display over the past few decades. A stop by any disposal and waste collection company in the country will reveal how much technology has changed the way garbage is collected and disposed of.

For example, there are automated sensors that give alerts when containers are full and they need to be serviced. Magnets, optical sorters and disk screens all work together to separate and identify recyclable waste.

Trucks that are used to transport the waste run on natural gas that has been compressed. This is a quieter and cleaner alternative to using diesel. Or click https://blackplanet.com/bestonmachinery to see other recycling methods.

In addition, the trucks are more efficient because they use logistics software and apps to plan pickup routes.

Landfill Modernization

The waste and recycling industry has been able to harness efficiency when it comes to science and scale. Landfills have become much more than garbage dumps. They are highly engineered, and they operate under very stringent state and federal regulations.

These regulations help to ensure that the environment and the public’s health are both protected. The landfills of today not trap gases, and these gases are used to heat homes and offices.

Finally, landfills are not able to perform carbon sequestration. This is a process that prevents carbon from reentering the Earth’s atmosphere.

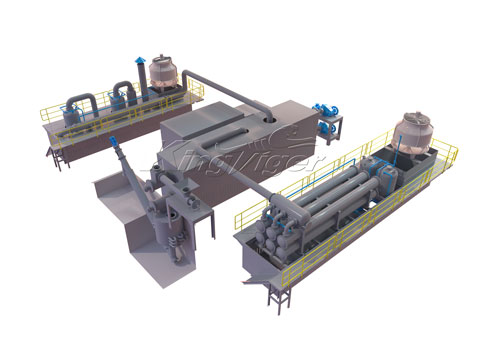

The waste ecosystem has never been more complex than it is right now, and the waste and recycling industry has expanded to meet the ever changing needs. Garbage recycling plants and other advanced technology have helped to reduce the industry’s impact on the environment. Consult good waste sorting machine cost from Beston. Besides, this company also provides waste pyrolysis machine UK.